Toll Free:

1-877-270-9985, Phone:

519-653-1301, Fax:

519-653-2253

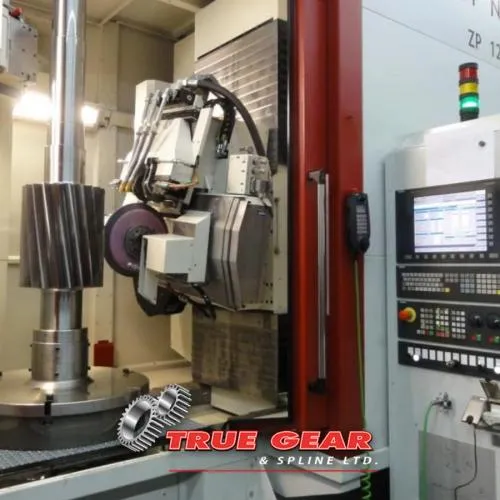

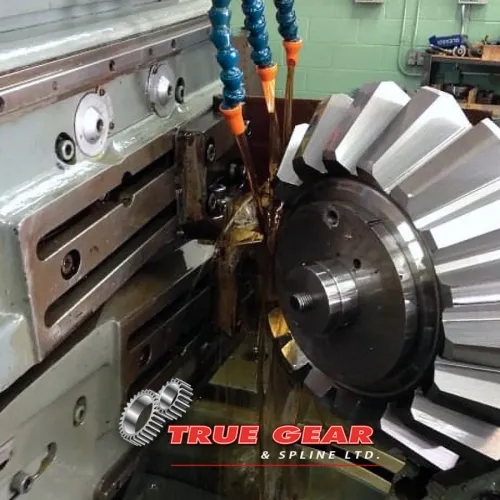

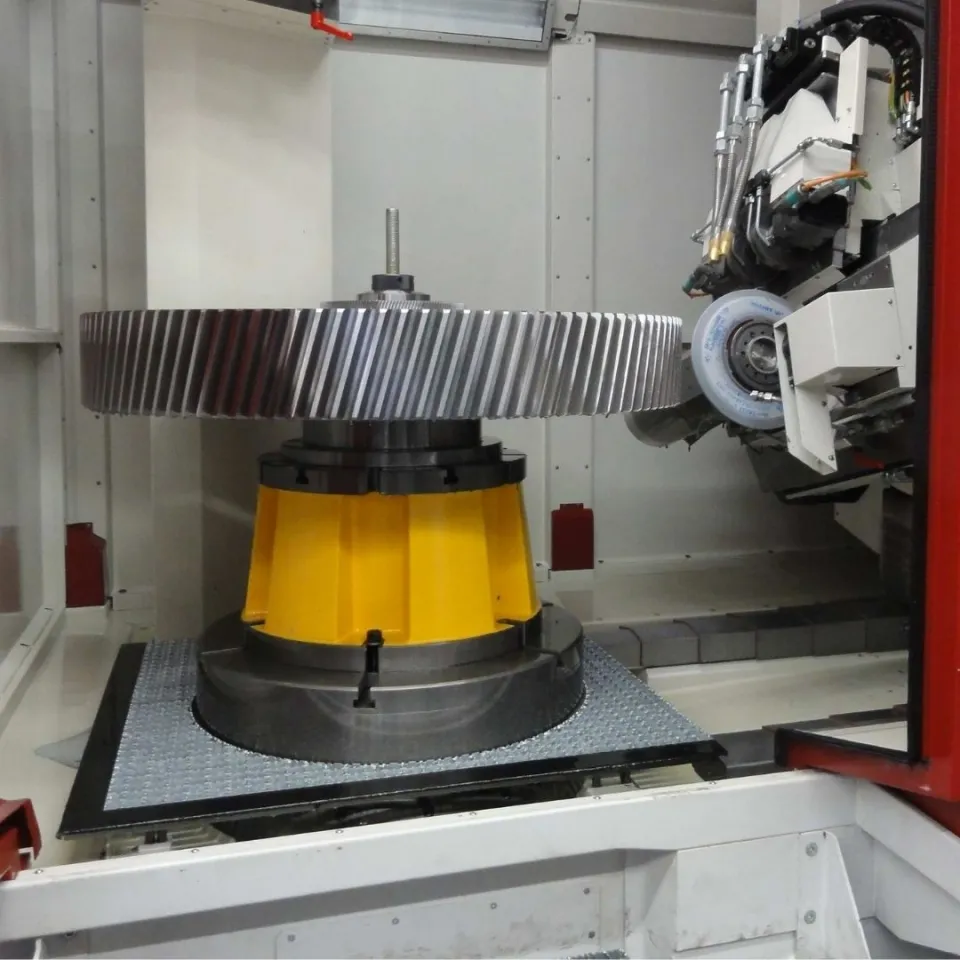

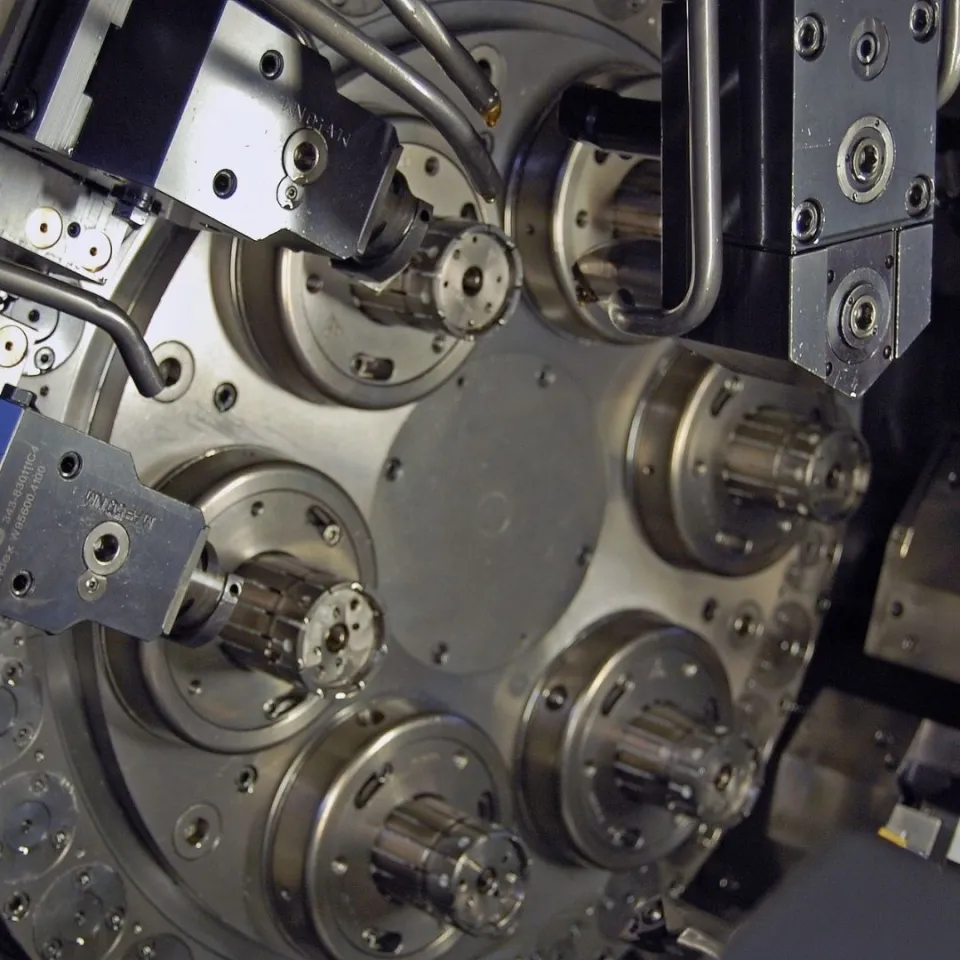

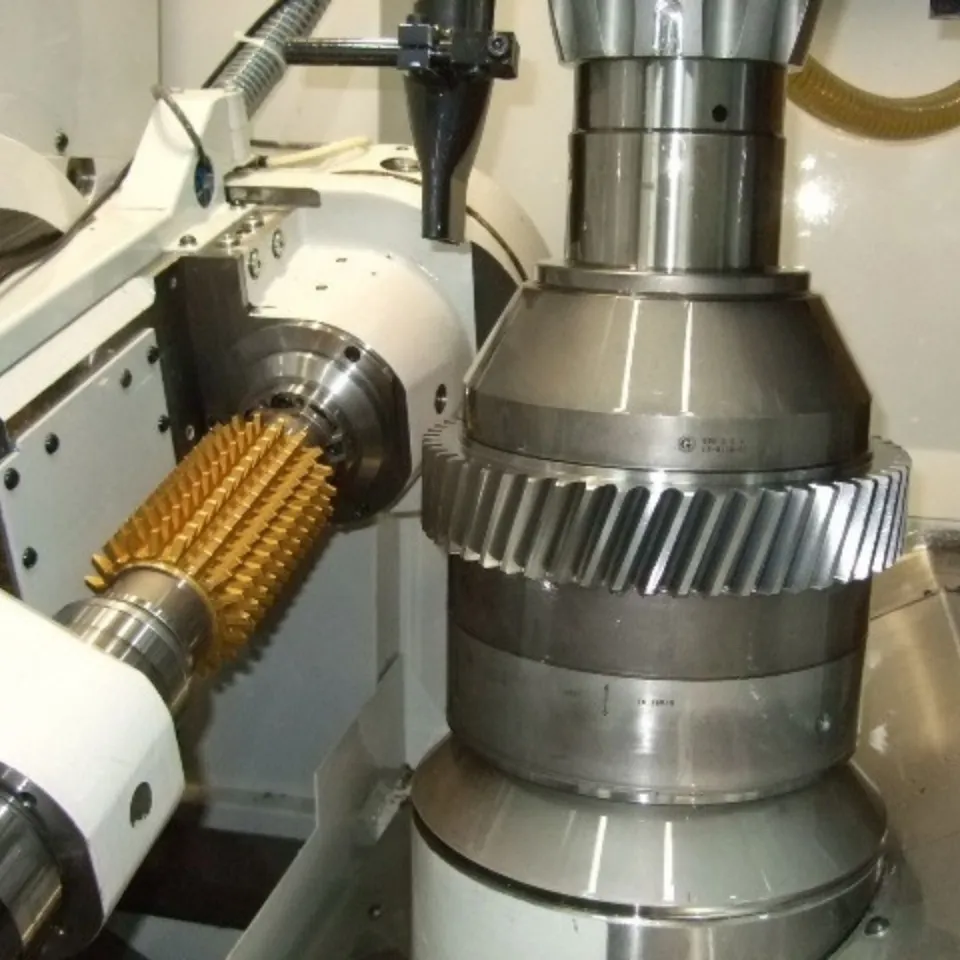

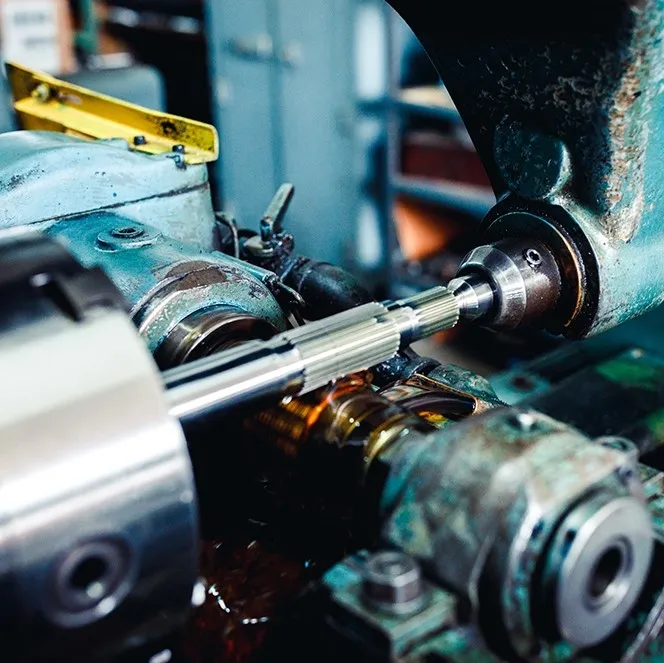

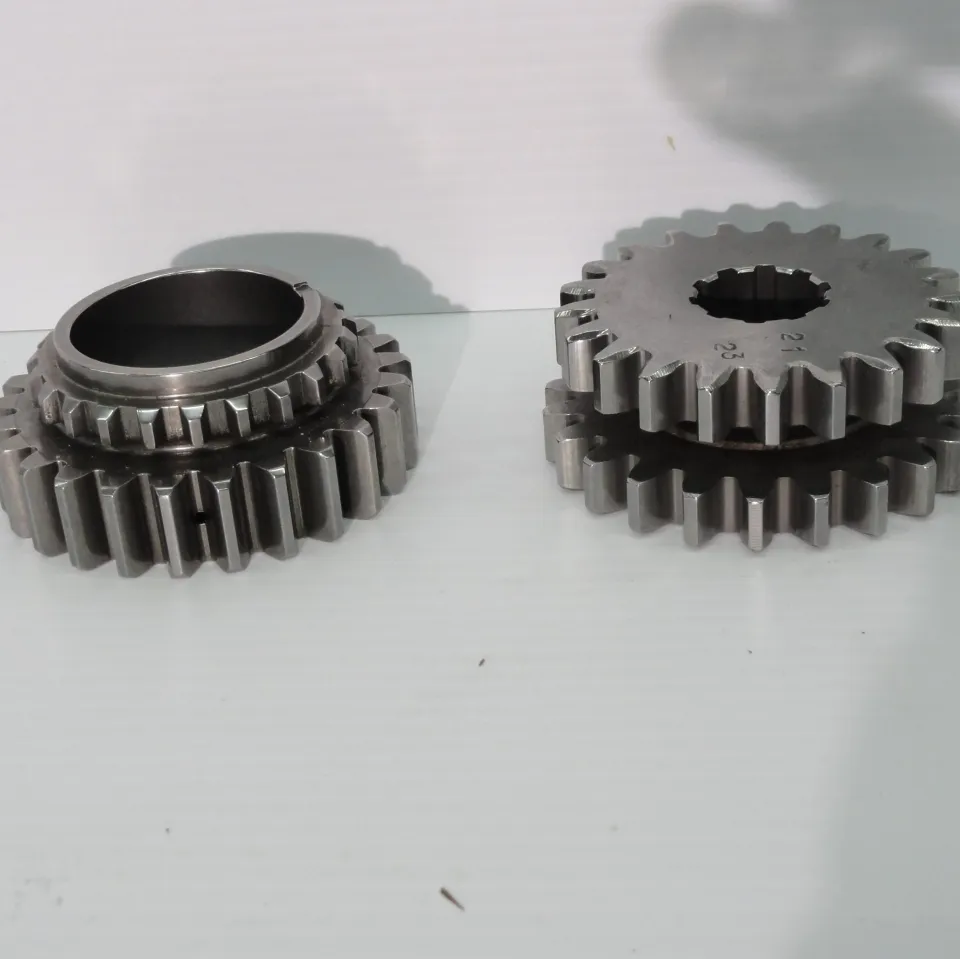

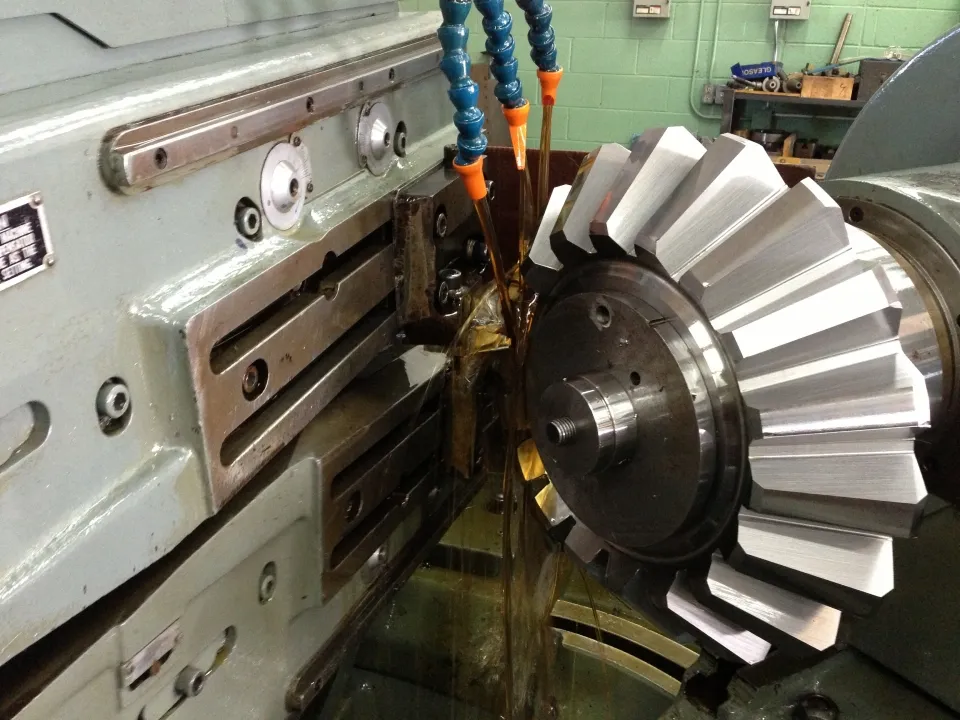

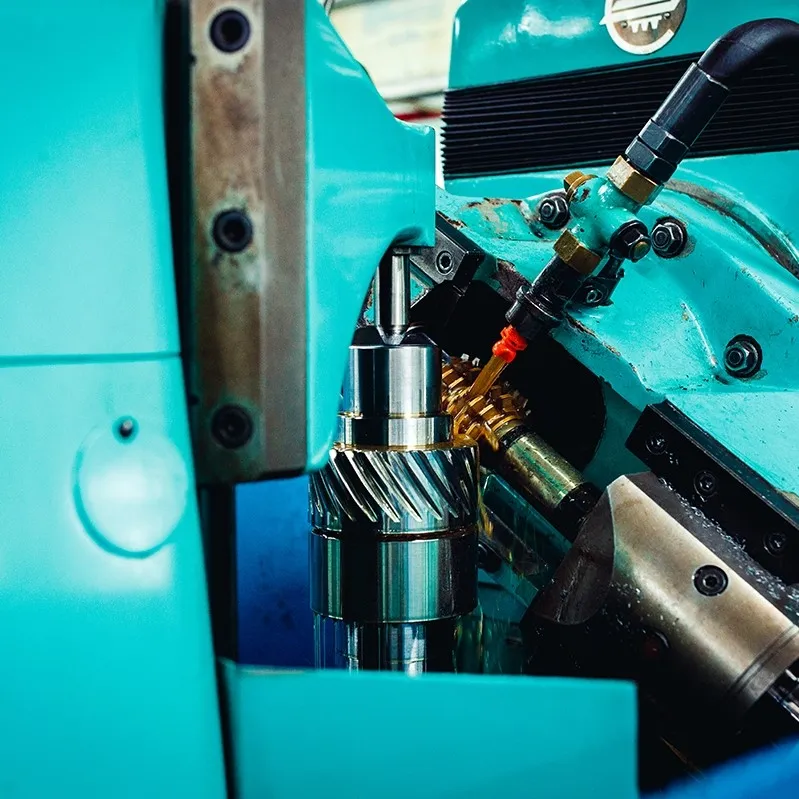

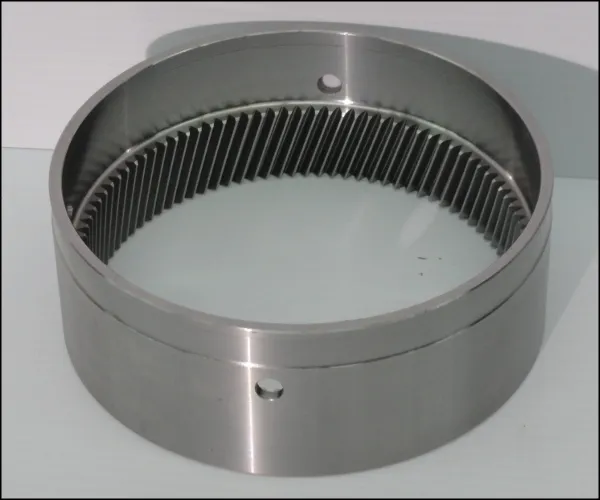

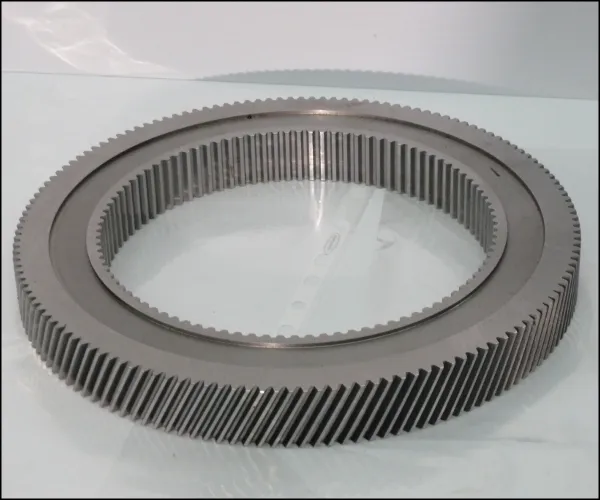

Precision Gear News & Updates

Request a quote today and discover why industries across North America trust us for their gear manufacturing needs.